NASA, We Have a Problem

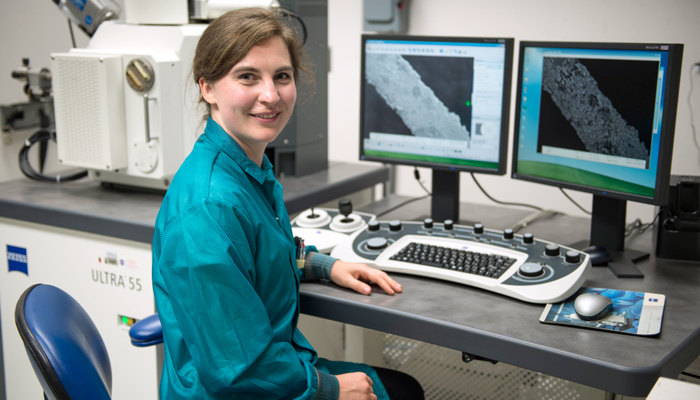

Lyudmyla Panashchenko ’05 loads a sample into her scanning electron microscope, which can produce an image up to 100,000 times its size using a focused electron beam. Photos by Pete Vidal.

When she activates it, the SEM will pump the chamber with the sample down to a vacuum and trace a focused electron beam over the sample and generate a high resolution image, magnified anywhere from 3 to 100,000 times its normal size. She can tilt the sample to view it from different angles and vary contrast and brightness to interpret the image. She looks for deficiencies in the component that might explain why it failed—or why it might fail—when circling the Earth inside a multi-million-dollar satellite. Panashchenko’s work in the Electronic Parts and Packaging Department at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, helps reduce the risk and expense of failures.

When parts fail on satellites already in orbit, the team uses information feeds from the satellite to backtrack from the point of failure. In the lab they sometimes have equipment identical to the orbiting equipment, which they can work on to find fixes. In her six years at Goddard, Panashchenko has tested, prevented, and/or analyzed failure on some historic projects.

When Panashchenko started as a mechanical engineering student at MC, she had no idea that path would lead to a stellar career at NASA.

Her team, for example, identified a faulty chip on a part destined for a NASA-operated mission for the National Oceanic Atmospheric Administration’s (NOAA) ICESat-2, set for launch in 2017. The satellite will gather data and measure ice elevations, sea-ice thickness, and vegetation canvases in Greenland and Antarctica via laser technology. The data will be used by NASA’s Earth Science team.

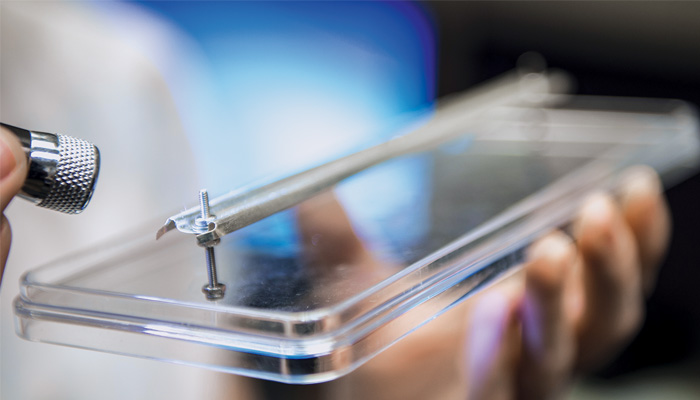

In 2010, when Toyota Auto Manufacturing and the Department of Transportation asked NASA for assistance finding cause for its accelerator pedal problem, which led to a large consumer recall, Panashchenko was part of the team that reported finding “whiskers” present on internal parts—not the kind that grow on chins of hipsters and lumberjacks, but the metallic variety that sprout (only sometimes) on electronics components when tin, zinc, and other alloys are present. The tiny growths, measuring from 1/10 to 1/100 in diameter of a human hair, are often undetectable by human eye. Typically, only an SEM can reveal their presence. Because they are conductive, whiskers can cause electrical disruptions and failures. Panashchenko researched tin whiskers extensively as a graduate student at University of Maryland. She says coatings sometimes help prevent their occurrence but scientists have yet to be able to predict when and how whiskers grow, or how to eliminate them altogether. Tin whiskers have caused the destruction of the Galaxy IV, Galaxy IIIR, and Solidaridad 1 satellites.

Shining a light onto the bar reveals metallic whiskers large enough to see with the naked eye. The tiny growths can measure from 1/10 to 1/100 of human hair in diameter.

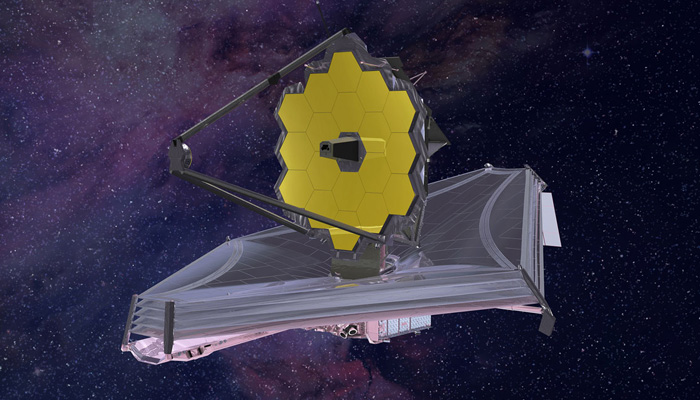

Last summer, she assisted in parts testing for one of NASA’s largest projects—the James Webb Space Telescope, or JWST. The JWST, sometimes called a “time machine” or “first light machine,” is the successor to the Hubble Space Telescope. It is designed to detect faint photons of light from the farthest reaches of our universe. Its primary mission will be to see further back in time than any human instrument ever—back to when the very first stars formed (some few hundred million years after the Big Bang—just a fraction of our universe’s 13.8 billion year history). It will also be able to study the composition of atmospheres on planets outside our solar system and perhaps one day even find a planet similar enough to Earth that can support carbon-based life.

The James Webb Space Telescope is the successor to the Hubble Space Telescope. Photo courtesy NASA.

“During testing, we mimic the extreme temperatures and vibrations that any spacecraft experiences during launch and orbit,” says Panashchenko. These grand-scale tests can sometimes fail due to minute problems. During the ICESat-2 testing, for example, a cracked solder joint failed during pre-launch testing and an entire scientific instrument stopped functioning. Ultimately, the team discovered that a well-meaning technician had re-applied heat to the solder joint used to attach the part to the circuit board. That extra heat took the solder mixture to a temperature above its melting point, dissolving additional metals into the joint and resulting in a weaker connection. After testing to demonstrate this effect on spare components, the team used X-ray to look for weakened joints on built flight hardware, and identified weakened components that were then replaced. Without on-ground testing, this failure would have likely resulted in loss of a satellite in orbit.

An artist’s rendering of the James Webb Space Telescope in space. Rendering courtesy NASA.

Panashchenko’s experiences at Goddard in failure analysis continue to challenge her. In addition to giving input on the ICESat-2, JWST, and Hubble Space Telescope repairs, she had the opportunity to examine samples from Space Shuttle boxes that were growing tin whiskers. She has mentored several graduate students and undergraduate interns via the Pathways program, a government-wide initiative that often results in employment opportunities for new talent. She has spoken at conferences, and she is part of a small group that maintains NASA’s metal whiskers website. Her thesis, “Evaluation of Environmental Tests for Tin Whisker Assessment” has been downloaded more than 5,000 times.

In January 2016, she returned to Montgomery College to talk to students about her work during the annual Maryland Science Bowl event—tin whisker samples in hand. “I am an expert on something so tiny,” she says, “but significant to an entire industry. I encourage students to expand their learning in new areas because you never know what will inspire and make you passionate until you try it.… My own interest in metal whiskers was an accident—I picked up a laboratory internship as an undergraduate where, over time, I got to run a graduate project (after a graduate student left). I found it so fascinating that I decided to stay for my own graduate degree and work further on these little things called tin whiskers. It was an accident, as I think many things are in life. But an accident that only happened because I tried something new.”

In January 2016, she returned to Montgomery College to talk to students about her work during the annual Maryland Science Bowl event—tin whisker samples in hand. “I am an expert on something so tiny,” she says, “but significant to an entire industry. I encourage students to expand their learning in new areas because you never know what will inspire and make you passionate until you try it.… My own interest in metal whiskers was an accident—I picked up a laboratory internship as an undergraduate where, over time, I got to run a graduate project (after a graduate student left). I found it so fascinating that I decided to stay for my own graduate degree and work further on these little things called tin whiskers. It was an accident, as I think many things are in life. But an accident that only happened because I tried something new.”

—Diane Bosser

Follow Us